Tools and materials required:

Tools and materials required:

- PEX tubing

- PEX cutter tool

- Brass or Poly PEX crimp fitting(s)

- PEX cinch clamps

- PEX cinch/clamp tool

Safety first - always wear appropriate eye protection gear.

Step 1:

Position the cutter perpendicular to the PEX pipe and make a smooth, clean cut.

Step 2:

Slide the PEX cinch clamp over the pipe.

Step 3:

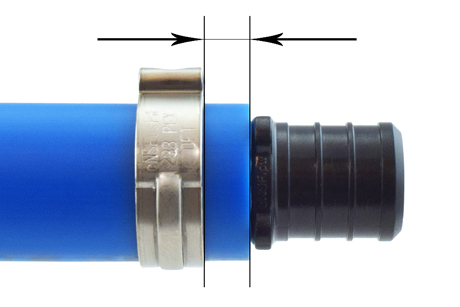

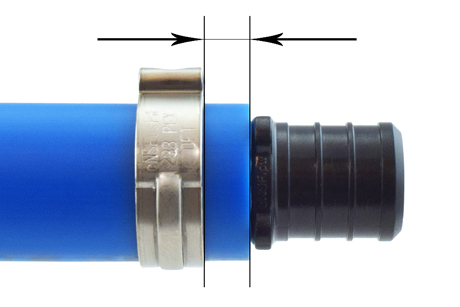

Fully insert the PEX crimp fitting into the pipe.

Step 4:

Slide the cinch clamp toward the fitting so that it (edge of the clamp closest to the fitting) is positioned 1/8" – 1/4" from the end of the pipe.

Step 5:

First, fully close the PEX cinch tool, so that the ratchet mechanism would release the jaws. Second, position the open jaws of the tool over the ear of the cinch clamp as shown.

Step 6:

Fully close the jaws of the tool. Ratchet mechanism will prevent early release and will not allow to open the tool until the connection is complete.

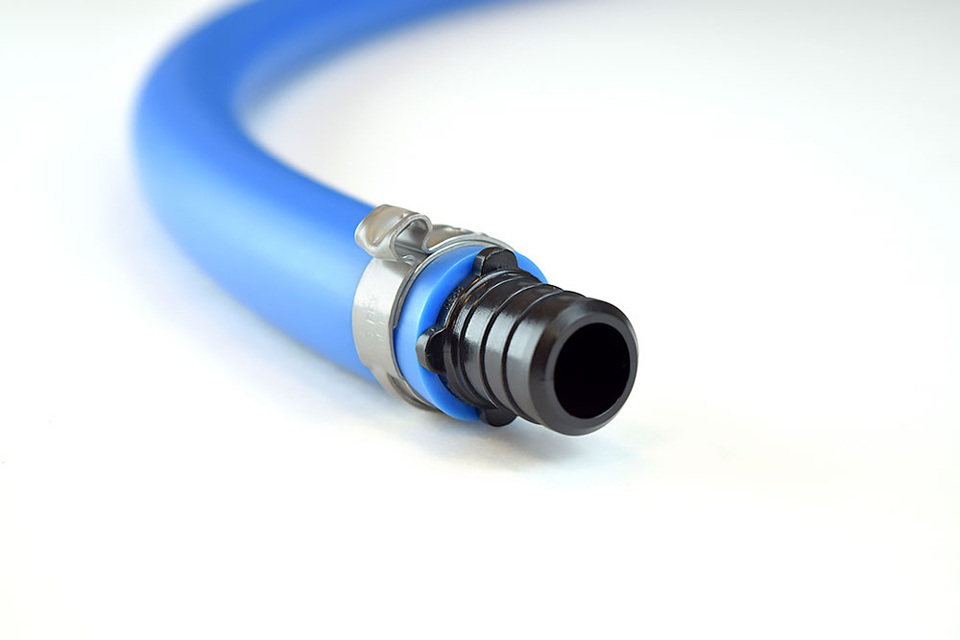

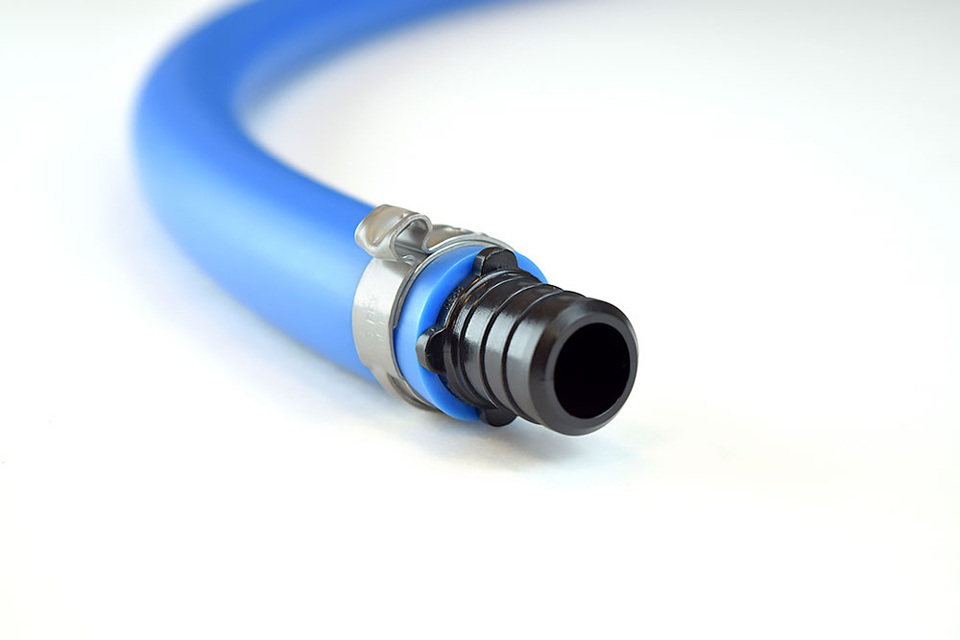

Connection is complete

A typical example of a completed connection is shown below. Always inspect it visually to confirm that the fitting is fully inserted and clamp’s edge within the acceptable distance from the pipe’s end.

Frequently Asked Questions:

Q:

Are fittings removable/reusable?

A: Yes. To remove the fitting, use wire cutters to cut off the ear of the clamp and pry the remaining portion with a flatbed screwdriver. After the clamp is removed, the fitting can be pulled out with a little effort.

Q:

Which type of fittings and pipe can cinch method be used with?

A: Cinch/clamp method works with crimp style

brass or

poly PEX fittings (poly PEX fittings shown in this tutorial) and with all types of PEX tubing (

barrier and

non-barrier, whether A, B or C types). This method is not compatible with PEX-AL-PEX tubing.

Q:

Which brand cinch clamps do you recommend?

A: We recommend

only the

Oetiker brand PEX clamps – these have the best quality (material type, strength and thickness) among all we’ve tested and they are the only NSF certified clamps on the market. In addition, these clamps have just the proper amount of lubricant sprayed on the inside (not outside) surface of the ring (clamp) which allows it to evenly compress over the pipe’s surface, effectively distributing the force without over-stressing individual points.

Q:

Which is better – clamp or crimp method?

A: We sell about an equal amount of crimp rings and cinch clamps. Clamps are growing in popularity since they are easier to install and the

PEX cinch tool is more compact then the crimp one, allowing to make connection in less accessible locations. In addition, cinch tool is universal and works with all clamp sizes, whereas crimp method requires a separate tool (or a change or tool jaws) for every PEX tubing size. However,

crimp method offers a somewhat more uniform and easily gauge-able connection, and has decades of proven performance, which makes is a popular choice among professionals and DIY’ers alike.

Q:

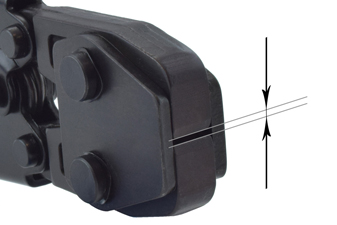

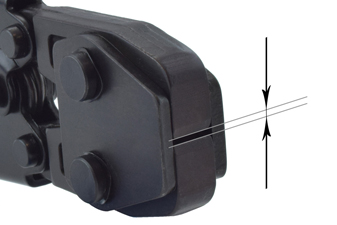

Is there a gauge tool for the cinch clamps?

A: PEX cinch/clamp tools sold at PexUniverse are factory-calibrated and do not require initial adjustment. To check whether the tool is properly calibrated, use a depth gauge. The jaw opening of the tool in a fully closed position should be between 0.8-1.2mm.

See picture for reference.

Tools and materials required:

Tools and materials required: